Poultry Processing Line Speeds: An Infographic Overview

To help explain how poultry processing line speeds are determined, we broke it down into this infographic.

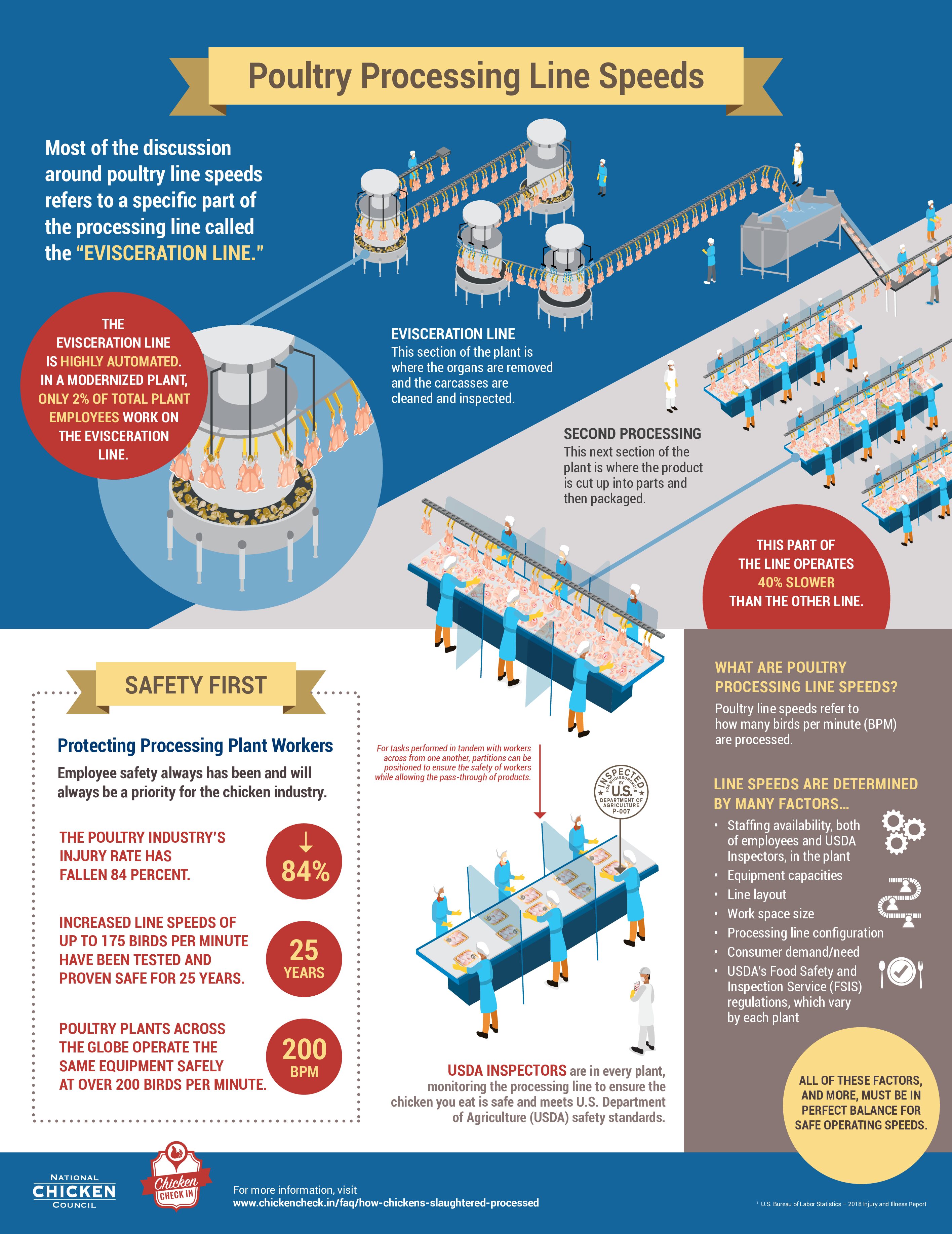

Poultry processing line speeds refer to how many birds per minute (BPM) are processed.

Most of the discussion around poultry line speeds refers to a specific part of the processing line called the “evisceration line.” This section of the plant is where the organs are removed and the carcasses are cleaned and inspected.

The evisceration line is highly automated.

- In a modernized plant, only 2% of total plant employees work on the evisceration line.

After the evisceration line, “second processing” is the next section of the plant where the product is cut up into parts and then packaged.

- This part of the line operates 40% slower than the other line.

Line speeds are determined by many factors…

- Staffing availability, both of employees and USDA Inspectors, in the plant

- Equipment capacities

- Line layout

- Work space size

- Processing line configuration

- Consumer demand/need

- USDA’s Food Safety and Inspection Service (FSIS) regulations, which vary by each plant

All of these factors, and more, must be in perfect balance for safe operating speeds.

Protecting Processing Plant Workers

Employee safety always has been and will always be a priority for the chicken industry.

- The poultry industry’s injury rate has fallen by 84 percent.

- Increased line speeds of up to 175 birds per minutes have been tested proven safe for 25 years.

- Poultry plants across the globe operate the same equipment safely at over 200 birds per minute.

Learn more about line speeds in the United States: https://www.chickencheck.in/faq/poultry-line-speed/