#RaisingPoultry :: Bye Bye Birdie

This blog post was originally drafted and posted by Lauren Arbogast of Paint The Town Ag. It is part of a blog series dedicated to #raisingpoultry. In the series, Lauren walks us through how poultry is raised in the United States – from start to finish.

Lauren and her family raise chickens and cows in beautiful Virginia. Check out the original blog post, and Lauren’s Twitter and Facebook pages.

>>><<<

So we’ve been through the set up, baby days and teenage peep show. You know what goes into the bedding, how Farmer is literally a jack-of-all-trades, and how the mini-farmers help occasionally (or just get stuck in buckets). There comes a time to say goodbye to our feathered friends.

Farmer contracts with a certain company, like many other poultry farmers do. This company (like other, similar poultry companies), harvests the birds at a certain weight in order to meet the requirements of their buyers. Buyers are defined as the last stop prior to the consumers – for example: restaurants, grocery stores, markets, etc. When you see chicken breasts in the grocery store that are different sizes, it’s because they came from different size birds. There are no steroids or hormones involved, like I discussed in this post, they are simply different size chickens.

A few days prior to the birds leaving, they are periodically weighed and evaluated to measure overall readiness. A schedule is set up through the company for their departure, and it includes what houses are leaving and what time the crew and trucks will be there.

On the day and time of departure, a “catch crew” arrives with their equipment and tractor trailers with transport cages on them. These cages are much like a kennel or crate for your dog or cat – they are the appropriate size for the bird being transported to give adequate room for an (often) short trip to the processing plant. In inclement weather and in the winter, the cages have sides on them to protect the chickens from the weather.

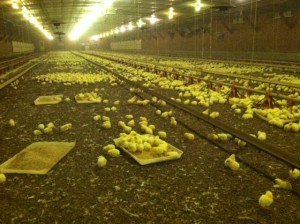

The crew starts by putting a large fan in the far door (think: larger than garage door) at the end of the house that pulls air across the birds. The large door on the front end of the house is also opened, and the lights are turned off so that the birds sit quietly on the floor and aren’t spooked. The feed and water lines are raised to the ceiling to get them out of the way, and so begins the process of “catching” the chickens.

Let’s define “catching,” shall we? It’s not a game of chase, nor is it anything like playground tag. The environment in the houses is such that the birds are literally sitting down and calm when the crew puts them into the transport cages. That’s “catching.”

A team of men (no offense ladies, I’ve just only seen men do this job) starts at the end of the house opposite the fan. A forklift-like vehicle (see the picture below) takes a transport cage off the tractor trailer and puts it directly behind the team. The cage is approximately 4 x 5 x 8 and has multiple levels and compartments. The crew picks up the chickens and puts them in the compartments, and each individual compartment is latched. Once full, the forklift carries the transport cage and gently sets it on the trailer to be locked into place. Another empty transport cage is delivered into the house, and the process continues until all of the chickens have been loaded.

All in all, it takes approximately three hours for an entire house to leave. Keep in mind, these time frames and any specific numbers mentioned are specific to our houses, farm, and company. Regardless, across the poultry industry, the process of taking chickens to harvest is very humane, efficient, and organized.

And so it all begins again, literally as soon as the house is empty. Farmer can often be seen cleaning out or windrowing one of our chicken houses while another house is being loaded for harvest. He wastes no time in readying the houses for new peeps.